This post is an Introduction to cnc router for beginners. It’s meant to get the beginner accustomed to a CNC routers and some terminology used in operating CNC routers.

What is a CNC router?

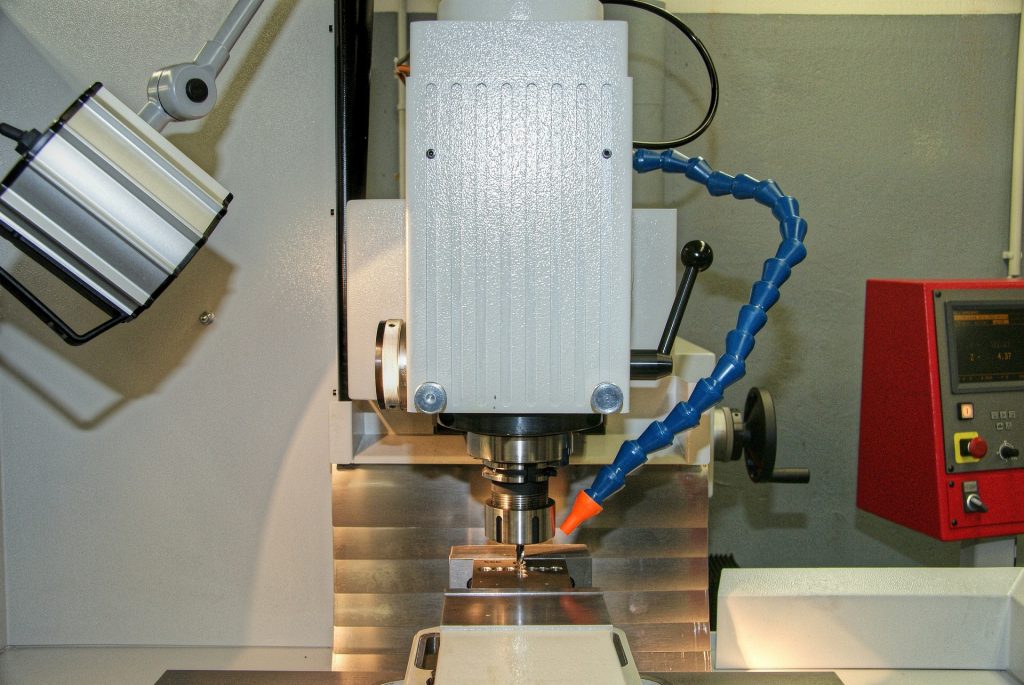

CNC stands for Computer numeric control. So a CNC router is a computer numeric controlled router. This is a router controlled digitally by a computer through a controller interface.

The level of control may vary depending on the type of CNC router being used. A cnc router can have near absolute control over the operation of the router. The variables that can be controlled include the RPM of the router, the direction of movement of the router, the rate of movement, acceleration of the movement.

A cnc router produces items from stock material by a subtraction method, it continues to chip out from the the stock material until the production is complete. To achieve this it uses various types of tools called endmill or bits. The type of bit used is determined by the product desired as some products can only be produced by a particular type and size of bit.

The control signals are passed on by the computer via the controller and are often very precise and much more accurate than what a human can do.

CNC routers can come in various degree of control of movement called axis. We will be focusing on 3 axis CNC routers.

3 axis CNC router

A 3 axis cnc router can control the movement of the router in 3 axis namely x axis, y axis and z axis. This is linear movement on all directions on horizontal plane, and vertical up and down linear movement. Most common CNC routers used by industries and hobbyists come in this variant.

It will work effectively on surfaces that are planer. It expects to be fed with a flat rigid material from which it will produce items in 2 dimension or 2.5 dimensions based on the instructions. The 3 axis cnc router come in various sizes determined by maximum length, width and depth of material it can work on.

To produce items based on the designs produced, the designs first has to be converted into CNC router instructions. These instructions are called gcode. The gcode for a particular design can be written by a gcode programmer or by some softwares called Computer Aided Manufacturing (CAM) softwares.

So in order for an item to be produced by a cnc router it needs a flat material to cut and the gcode that will control its movement, speed, acceleration, spindle speed (RPM) and depth of cut. Many 3 axis CNC routers control only the movement, speed and acceleration of the router, while the spindle speed is controlled manually by the operator.

Some terminology used in CNC operations.

Feedrate:

This is the rate of movement along the various axes of the machine. It is measured in inches per minute (IPM). This parameter can be set in the gcode instruction file or set manually on the controller. This parameter is very important because it determines if the operation will complete successfully and varies for different materials and different bits. A wrong feedrate can break the bit, damage the material to be worked on, produce less than desirable surface finish or take forever to finish a simple task.

Toolpath:

The toolpath is the programmed path and direction of movement required to complete a particular task. It is often generated by the CAM software taking into consideration the tool type size and design to be machined. The toolpath is stored as gcode instruction.

Stepdown:

This is the incremental distance the router is moved downwards in the z axis. Stepdown is important when the desired depth of cut is too deep to be cut in one pass. When cutting deep into hard materials like stone or metal it ensures the tool is not damaged. It allows the machine to chip off the material a layer at a time.

Stepover:

This is the distance between adjacent toolpaths. It’s often measured in percentage of the cutting tool diameter. This value can determine how smooth a piece will be after machining. Large values can result in lines along the toolpath.

Read more on deciding to build or buy a CNC.