Introduction

Building a DIY cnc router project can be fun and challenging. True one never fully understands the extent of application of the CNC router. It is amazing applying CNC routers to processes that are usually manual.

There was need to have many computer tables in a facility. This is aimed at aiding elearning due to the Covid-19 pandemic. Supplying ready made computer tables is the preferred option for various reasons favorable to the organization.

Due to interstate lockdown, computer tables are out of stock in the city. I said why not make one with a DIY CNC router. If the design is good, applying a CNC router will enable the organization meet the short notice to supply. Another advantage is that there will be consistency in the output thus creating a uniform appearance.

Survey

To design a computer table similar to what is available in the market, will require a market survey. The survey would reveal what types of plywood boards available and their thickness. My intention is to easily assemble this table after cutting on the CNC router and it will hold without screws.

The boards that appealed to me was MDF boards. My survey showed there is enough supply of 3/4 inch MDF boards available in many stores. Determining their thickness is key, and most of them measured 16mm in thickness. To achieve a snug fit, this thickness will be the basis for the design.

Design and cutting DIY cnc project

I set the length, width and height of the finished table in a sketch. This information I set out to implement in a CAD software. For any DIY cnc project, the success depends a lot on the design. In creating this project I knew the time spent on the design and CAM creating gcode will be worth it. Getting it right albeit with many revisions will ensure smooth production runs on the DIY CNC router.

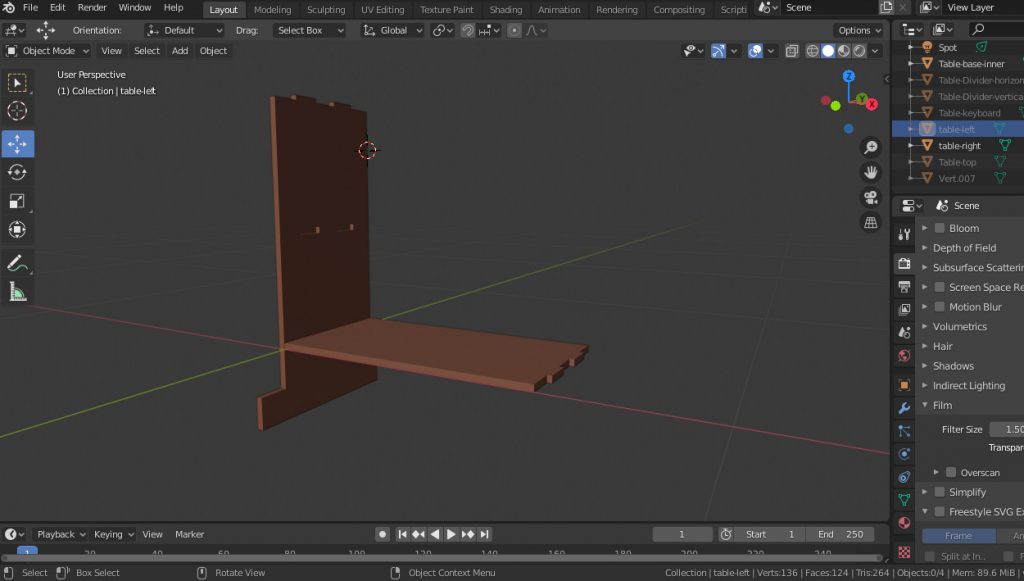

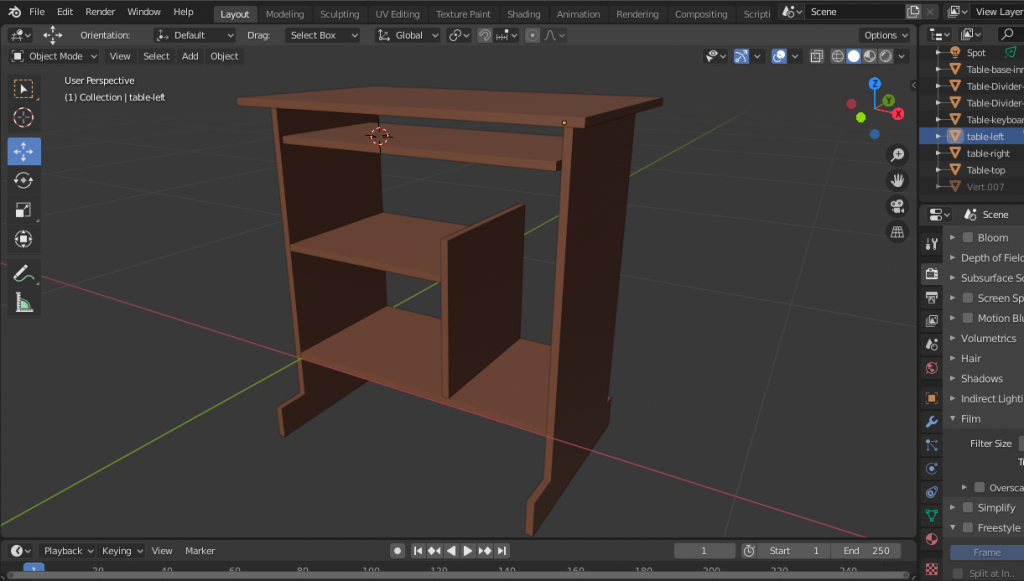

Starting base with the length, width and height of the table, I design each component to fit into the adjacent component. The design was done in 3d using blender a free CAD software though geared more toward art designs.

The picture below is the computer table after modeling. The 3d software blender provides the ability to inspect the various components and joints. Making sure every slot fits snug with its plug was very necessary.

With the table design complete gcode generated in a CAM software I set out to the machine for the next phase of the DIY CNC project. The total machine time was about 40 minutes at 2000mm/min feedrate. There are holding tabs for each component.

The board is taken off the cnc machine and the process of tapping exposed edges is done and this below is the final result for the DIY cnc project.