Engraving is an art that has been with man from the stone age to present times. It is the art of marking a hard surface with a design by displacing top particles of the surface with a tool. Various tools are used for engraving on different materials. The tools are generally harder than the surface you will engrave.

The tools that can be used for this art have evolved over time. These range from stone through burin, electric hand engraver to CNC laser or router. A CNC is one of the most modern tool for tool at the moment. We will focus on engraving using a CNC router in this post.

Engraving Using CNC router – the process

A CNC router provides great improvements in the engraving process. It enables very complex designs to be engraved on a material with near precision. This improvement is not limited to how precise it can engrave but also in the time it takes to complete an engraving task. Master pieces that normally takes a skilled hand days or weeks can be done in few hours using a CNC.

With the improvement in efficiency and results achieved with a CNC there are also some limitations. What most CNC routers can engrave are limited by their size. The work piece will most certainly pass through the CNC before installation. This makes it difficult to engrave on objects in situ like engraved rock monuments.

Design and material selection

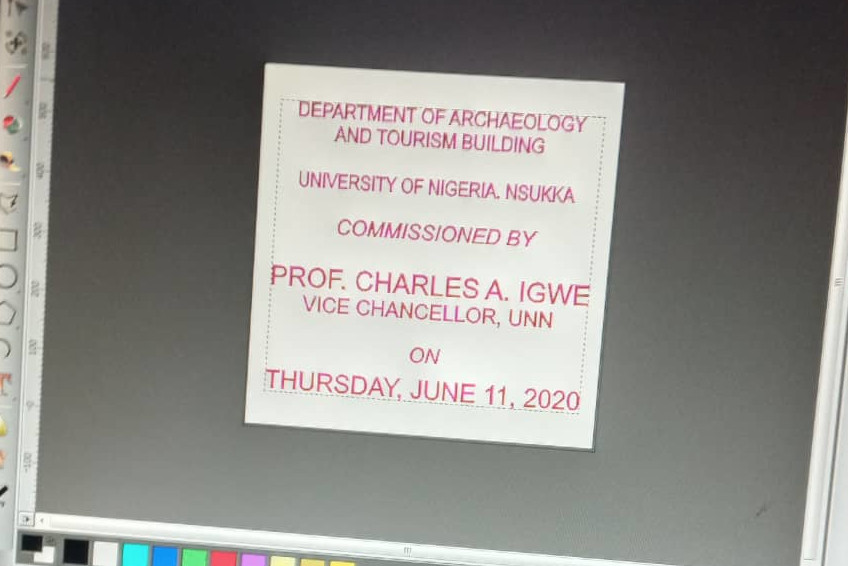

The first step in engraving with a CNC router is to have a design that you wish to engrave. It may be on a piece of paper which will have to convert into a CAD by a software. With your CAD design you will be able to use a CAM software to produce the gcode instructions that the CNC will use. We will discuss more on this so read on. While selecting the design it is helpful to have the material of choice into consideration.

The 3 axis CNC router will be most effective engraving on a material that has its surface parallel to the XY plane. It is also essential that this surface is evenly flat to produce uniform results. When the surface is not even, you may need extra time to level off the surface. This leveling involves removal of material from the stock using some tools or a CNC.

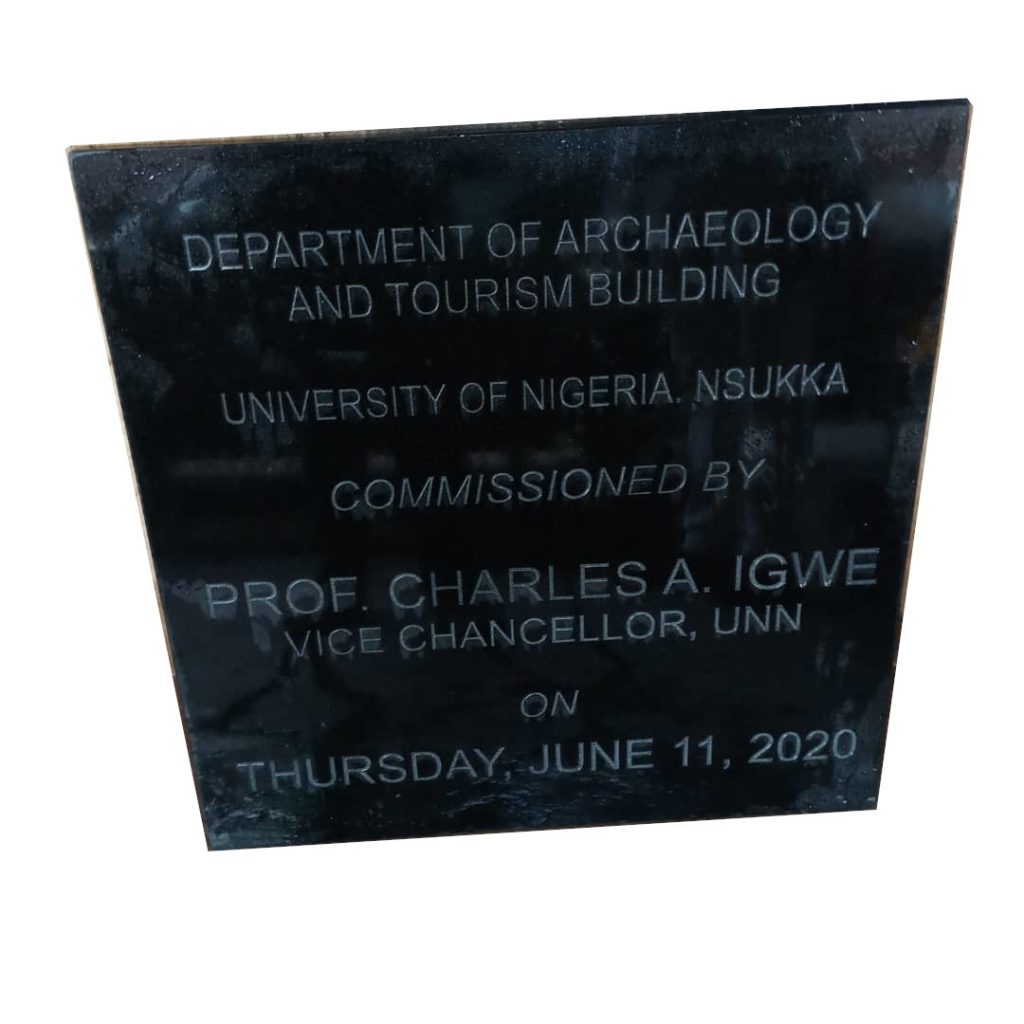

Here we want to engrave on a black stone (granite) slab. We measure the stone to verify that we have even thickness. This particular slab has even thickness so we clamp it on the CNC table. Where the stone have uneven thickness we support it while clamping. Their surfaces are polished and hard so leveling is not an option.

CNC router bit selection

With our our material clamped and the design ready, it is time to choose the CNC router bit. We will be using a vbit for this piece. The finished work will have a v groove round through letters we will engrave. Granite is a very hard material. There are vbits made for working on marble and granite. Most of them are diamond tipped and may require water based coolant while working.

There is also the option of using a diamond tipped impact vbit. We use these impact bits when we desire a result that is not deep. They work by displacing the top particles on the surface we engrave. Our desire for this work is a result that has visible and physically felt v groove all through the letters. Hence our selection of a 30 degree diamond tipped vbit.

With the bit in mind we create a toolpath for the bit we will use. A pocket toolpath operation or a vcarving operation will produce the look and feel we want. We decide to go with a v carving or v-engraving operation. To prevent fast tool burnout we also choose a feedrate of 900mm/min for this bit.

Engraving the granite

With the toolpath ready we load the gcode file into the CNC controller. The gcode we are using reference the bottom left top of the material as the origin. We move the router spindle to the bottom left and move the vbit negative z till it just makes contact with the top of the granite. Here we mark as the origin. This means the CNC will mill the design into negative Z to engrave on the granite.

The CNC spindle speed we set is 24000 rpm as the CNC router moves through the material milling out the design. We provide adequate supply of water as coolant to the vbit tool. The engraving took about 100mins to complete.

Below is the piece still wet fresh off the CNC router..